Like an ever growing number of companies, Toyota Motor has for many years released annual sustainability reports. That includes focused regional editions in addition to a global report, and TheGreenSupplyChain just took a look at the company’s just released European report, which was quite interesting. (To download full copy, go to Toyota European Sustainability Report.)

In the report, the company notes progress in the area of car design to reduce emissions and its ability to avoid layoffs in Europe, despite the brutal shape of the car market over the past year. Here, however, we focus on the supply chain aspects of the report.

This is the eighth such report, and Toyota obviously takes Sustainability very seriously – its stated goal is to be “the environmental leader” in every market that it serves. It also has a rolling 5-Year Environmental Action Plan to ensure its goals are reflected in actual investment and execution.

It also notes its Sustainability metrics are produced using ISO-certified processes for quality, and that the data collection is based on the Greenhouse Gas (GHG) protocol of the World Business Council for Sustainable Development (WBCSD) and the World Resources Institute (WRI).

Volume Declines Make Improvement Tough to Achieve

In 2008, Toyota Europe cut CO2 emissions from 339,000 metric tons in 2007 to 261,000, or a decline of about 23%. However, vehicle production dropped by 27%, and emissions per vehicle actually increased. That makes sense, in that there is a large amount of fixed CO2 emissions for any given factory, and producing fewer cars in a year would therefore tend to increase the average per vehicle. However, the report says CO2 levels are down 4.2% from the last year (2004) with similar production volumes in Europe.

It also says that there has been steady progress, in general, over the past eight years. The report says its is using the Lean concepts in its Toyota Production System (TPS) to also reduce CO2 emissions and achieve other related Green supply chain goals, which has led to a reduction in its per-vehicle energy consumption in the production process by 38% since 2001.

Each European plant now has a Key Performance Indicator (KPI) associated with carbon emissions. In addition, the company says it has picked plants in Great Britain and France to focus on how the factories could be converted to renewable energy sources.

Interestingly, of all its some 7 European plants, it has only one, in the UK, that is subject to carbon emissions limits under the EU’s cap-and-trade program. That plant in Burnaston used only 6,916 tons of its 17,535 tons CO2 allocation.

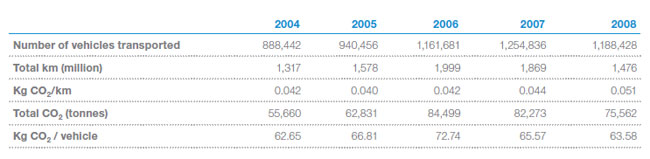

The company has also been looking to reduce emissions associated with its logistics processes and says it has achieved significant positive results through measures such as improved assets utilization, sharing vehicle transportation with other companies, and modal shifts. However, again here the reduction in CO2 from logistics is lower than the decrease in vehicles produced and it is assumed moved, as shown in the graphic below.

Toyota's Progress on the Logistics Front

It has a stated goal of 10% reduction in CO2 emissions per transported volume by 2010.

On the procurement front, Toyota Europe is finalizing a new Sustainable Purchasing Guideline, a version of which will be shared with suppliers.

In total, the report shows an impressive total company effort across a broad range of Green Supply Chain measures – but how tough progress really is.

Any reaction to the Toyota Europe Sustainability report for 2009? Let us know your thoughts at the Feedback button below.

TheGreenSupplyChain.com is now Twittering! Follow us at www.twitter.com/greenscm

|